Study on the effect of melamine on the growth of streptococcus thermophilus

Tech Blog Study on the effect of melamine on the growth of Streptococcus thermophilus Streptococcus thermophilus is a key lactic acid bacterium widely used in

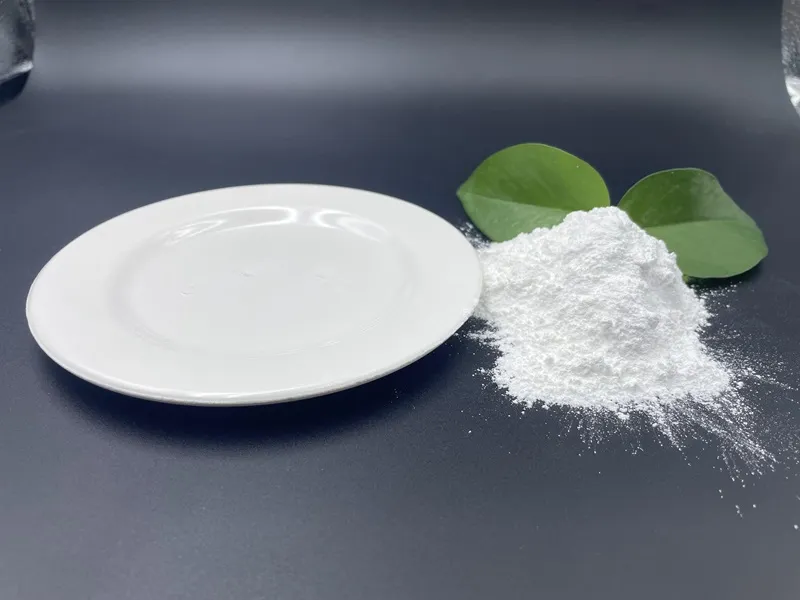

Preheating Process: Raw materials are weighed according to the required weight of the dinnerware, preheated uniformly to form powdered blocks.

Surface Treatment Process: The preheated and clumped raw materials are poured into molds and subjected to high-temperature and high-pressure curing to solidify and form the product.

Decal Process: Decorative paper with gloss powder is cut into desired shapes and carefully applied to the surface of the tableware. The decal should be positioned correctly for aesthetic appeal and then mechanically printed.

Gilding Process: After applying the decal, the product surface is evenly sprinkled with gloss powder. Excessive or inadequate application can affect the color and gloss of the product. The product is then cured under high temperature and pressure to achieve a porcelain-like shine.

Polishing Process: Post-production, the product undergoes polishing to remove any rough edges that may cause harm to users. This step ensures a smooth and polished finish for enhanced aesthetics.

Inspection and Packaging Process: Following polishing, the product undergoes rigorous quality inspection to ensure standards are met. Only approved products proceed to packaging after initial and secondary inspections, with any substandard items being removed from inventory.

Of course, to produce best melamine dinnerware, in addition to strict control in the production process, high-quality raw materials are also crucial.

As a professional melamine tableware raw material factory, we always adhere to the persistent pursuit of quality. We start from the source, producing urea, melamine powder, and melamine moulding compound. We have advanced production equipment and a strict quality testing system, conducting rigorous inspections on every batch of products to ensure their purity, stability, and safety meet the highest standards.

If you are looking for raw materials for high-quality melamine tableware, please do not hesitate to contact us. We will work together with you to create a better future with professional services, high-quality products, and reasonable prices. Let’s work together to create safe, beautiful, and practical melamine tableware for consumers and contribute our strength to the development of the industry.

Tech Blog Study on the effect of melamine on the growth of Streptococcus thermophilus Streptococcus thermophilus is a key lactic acid bacterium widely used in

Tech Blog Melamine Modified Polyurethane Polyurethane (PU) is a versatile polymer celebrated for its excellent wear resistance, oil resistance, chemical stability, and strong adhesion to

Tech Blog Spectrophotometric Method for Melamine Detection The spectrophotometric method for melamine detection is based on the complexation reaction between melamine powder, formaldehyde, and carbonyl

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE