Study on the effect of melamine on the growth of streptococcus thermophilus

Tech Blog Study on the effect of melamine on the growth of Streptococcus thermophilus Streptococcus thermophilus is a key lactic acid bacterium widely used in

Plywood is a widely used building and furniture material, and enhancing its durability is crucial for its long-term performance.

Melamine powder has emerged as an effective additive that can significantly improve the durability of plywood.

This article will explore the various ways in which melamine powder achieves this.

Melamine powder forms a hard and impermeable layer when applied to the surface of plywood. This layer acts as a barrier against moisture, preventing it from penetrating into the plywood layers. Moisture is one of the main factors that can cause plywood to warp, swell, and deteriorate over time. By blocking moisture, melamine powder helps to maintain the structural integrity of the plywood.

In addition to moisture, it also provides resistance to a wide range of chemicals. This is beneficial in applications where the plywood may be exposed to cleaning agents, solvents, or other chemical substances. For example, in kitchen cabinets or laboratory furniture made of plywood with melamine coating, the material can withstand the regular exposure to various chemicals without being damaged easily.

The chemical resistance of the melamine layer also helps to reduce the risk of delamination. Delamination occurs when the layers of plywood separate due to the effects of moisture or chemical reactions.

The melamine coating bonds tightly to the plywood surface and between the layers, providing additional adhesion and preventing the layers from peeling apart. This ensures that the plywood remains a unified and durable structure even in challenging environments.

Melamine powder increases the surface hardness of plywood. The hardened surface is more resistant to scratches, abrasions, and impacts. In daily use, plywood with melamine coating can better withstand the wear and tear caused by handling, moving furniture, or other activities.

This is particularly important for applications where the plywood surface is likely to come into contact with various objects or be subjected to mechanical stress.

For example, in flooring applications, the increased surface hardness provided by melamine powder helps to prevent the plywood from being scratched by foot traffic or the movement of furniture. It also makes the plywood more resistant to damage from heavy objects being dropped on it.

The melamine layer also improves the impact resistance of plywood. When the plywood is subjected to impacts, such as from falling objects or during transportation and installation, the melamine coating can absorb and distribute the force more effectively.

This reduces the likelihood of the plywood cracking or breaking. The improved impact resistance not only enhances the durability of the plywood but also makes it more suitable for applications where it may be exposed to accidental impacts.

Melamine powder provides thermal stability to plywood. It can withstand a certain range of temperature changes without significant degradation or deformation. This is important as plywood may be exposed to different temperature conditions in various environments, such as in buildings with heating and cooling systems or in outdoor applications where it is exposed to sunlight and temperature fluctuations.

The thermal stability of the melamine-coated plywood helps to prevent warping or cracking due to temperature changes. It ensures that the plywood maintains its shape and structural integrity, even in environments with varying temperatures. This makes it a reliable choice for applications where temperature stability is a concern, such as in interior doors or furniture that may be exposed to different room temperatures.

Melamine powder has some inherent fire-resistant properties. While it is not a fireproof material, it can slow down the spread of fire and reduce the flammability of the plywood to a certain extent.

When exposed to fire, the melamine layer can char and form a protective layer that can help to insulate the underlying plywood and delay the combustion process. This added fire resistance can enhance the safety of plywood in buildings and reduce the risk of fire damage.

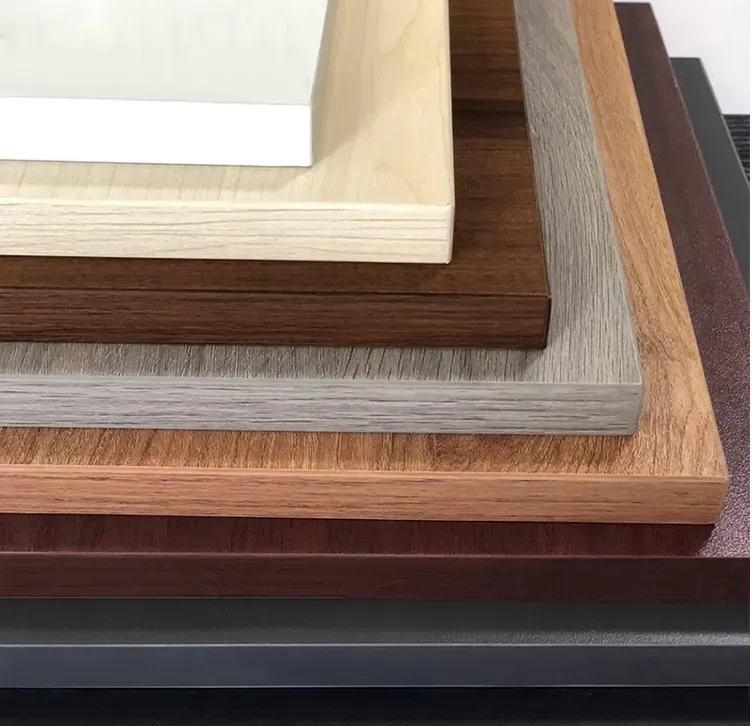

The melamine coating gives plywood a smooth and uniform appearance. It is available in a variety of colors and finishes, allowing for customization to match different design preferences. Moreover, the durability of the melamine layer means that the appearance of the plywood is more likely to remain intact over time.

Unlike uncoated plywood, which may fade, stain, or lose its smoothness, melamine-coated plywood can maintain its aesthetic appeal for a longer period.

This is beneficial for both residential and commercial applications. In homes, it can enhance the visual appeal of furniture and interior finishes. In commercial settings such as offices, hotels, and retail stores, the long-lasting appearance of melamine-coated plywood can contribute to a more professional and attractive environment.

The non-porous surface of melamine-coated plywood is easy to clean. It is resistant to stains and can be wiped clean with a damp cloth or mild cleaning agents. This makes maintenance of melamine-coated plywood relatively simple and cost-effective. In contrast, uncoated plywood may require more extensive cleaning and maintenance procedures to keep it in good condition.

The easy maintenance aspect of melamine-coated plywood also contributes to its overall durability. By being able to clean it easily, any dirt or contaminants that could potentially damage the plywood can be removed promptly, prolonging its lifespan.

Melamine powder enhances the durability of plywood through multiple mechanisms, including providing chemical resistance, increasing mechanical strength, ensuring thermal stability, and offering aesthetic and maintenance benefits.

By incorporating melamine powder into the manufacturing process of plywood or using melamine-coated plywood, manufacturers and users can enjoy a more durable and reliable building and furniture material.

This not only extends the life of the plywood products but also reduces the need for frequent replacements, contributing to cost savings and environmental sustainability in the long run.

Tech Blog Study on the effect of melamine on the growth of Streptococcus thermophilus Streptococcus thermophilus is a key lactic acid bacterium widely used in

Tech Blog Melamine Modified Polyurethane Polyurethane (PU) is a versatile polymer celebrated for its excellent wear resistance, oil resistance, chemical stability, and strong adhesion to

Tech Blog Spectrophotometric Method for Melamine Detection The spectrophotometric method for melamine detection is based on the complexation reaction between melamine powder, formaldehyde, and carbonyl

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE