Is Melamine Breakable?

Tech Blog Is melamine breakable? When looking for tableware that is both aesthetically pleasing and durable, melamine (also known as melamine resin) products are often

Melamine impregnated paper, also known as “melamine” paper, is a type of adhesive paper that has been impregnated with amino resins (including melamine formaldehyde resin and urea formaldehyde resin) and dried to a certain extent, possessing a certain resin content and volatile content.

This paper can be thermally pressed to bond with other sheets or with artificial board substrates, and is widely used in the manufacturing of flat-packed furniture.

Impregnation Amount: The solid resin in the impregnated paper, expressed as a percentage (%).

Volatile Content: The content of volatiles (mainly moisture and other small molecules) in the impregnated paper, expressed as a percentage (%).

Pre-curing Degree: The curing degree of the resin in the impregnated paper, expressed as a percentage (%).

Melamine impregnated paper was initially widely used in flat-packed furniture, mainly produced using low-pressure short-cycle pressing methods.

With technological advancements, synchronized patterned panels produced in conjunction with steel plate wood grain have become popular due to their excellent three-dimensional texture.

In recent years, the production of high-gloss panels through low-temperature long-cycle pressing has further enriched the product range.

To meet environmental requirements, especially the demand for formaldehyde-free products, melamine impregnated paper is also coated with water-based polyurethane resin after printing ink, to provide scratch resistance and enhance plasticity.

One of the key properties of melamine impregnated paper is its excellent surface hardness.

Once the resin solidifies, typically through heating and pressure, the paper forms a hard and durable surface. This makes it highly wear-resistant, making it suitable for applications where the surface may be frequently used and in contact. For example, it is commonly used in the production of reinforced wood flooring. The melamine impregnated paper on the surface of reinforced wood flooring provides a tough and scratch resistant layer that can withstand pedestrian traffic and furniture movement. It is also used to manufacture furniture surfaces, such as tabletops and cabinet doors. A hard surface can resist scratches from utensils, keys, and other objects, maintaining the appearance and functionality of furniture for a long time.

Another important feature is its heat resistance. Melamine impregnated paper can withstand relatively high temperatures without causing significant damage. This characteristic makes it very suitable for use on kitchen countertops and other areas where heat sources may exist. For example, hot pot or frying pan can be placed on a paper countertop soaked in melamine without immediately causing burns or warping. However, it should be pointed out that although it has good heat resistance, it is not completely heat-resistant and prolonged exposure to extremely high temperatures can still cause some degradation.

At the same time, in terms of aesthetics, melamine impregnated paper provides a lot of design possibilities. By adding different pigments and finishes, it can mimic the appearance of various natural materials such as wood, stone, and marble. You can use melamine impregnated paper laminates to achieve the appearance of luxurious hardwood flooring or smooth marble countertops at a very low cost.

Melamine impregnated paper, as an efficient and environmentally friendly surface decorative material, not only enhances the aesthetics and durability of artificial boards but also streamlines the production process, aligning with the modern furniture manufacturing industry’s demands for efficiency, environmental protection, and sustainable development.

It is anticipated that this product will occupy a significant position in the artificial board market and continue to drive the development and innovation of related industries.

Tech Blog Is melamine breakable? When looking for tableware that is both aesthetically pleasing and durable, melamine (also known as melamine resin) products are often

Tech Blog Is melamine recyclable Melamine-based products—from durable tableware to scratch-resistant laminates—are widely used in household and industrial settings due to their heat resistance, hardness,

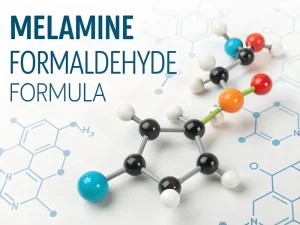

Tech Blog melamine formaldehyde formula What is melamine formaldehyde resin? Melamine formaldehyde (MF) resin is a high-performance thermosetting polymer known for its heat resistance, durability,

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE