Is Melamine Breakable?

Tech Blog Is melamine breakable? When looking for tableware that is both aesthetically pleasing and durable, melamine (also known as melamine resin) products are often

Melamine Moulding Compound (MMC) is a versatile thermoset plastic material composed of melamine and formaldehyde resins. Because of its unique properties, it is used in various industries, from tableware and kitchenware to automotive parts and electrical components. Let’s examine how its key characteristics translate to specific uses.

In the electronics industry, melamine moulding compounds make housings for various electronic devices. The material has excellent heat resistance and impact strength, making it ideal for housing components such as switches, sockets and connectors. In addition, the non-toxicity of melamine powder ensures that it does not pose any health risks in electronic applications.

Melamine moulding compounds are widely used in toys and children’s products because of their bright colours, variety of shapes and relative safety. The material’s drop resistance makes it suitable for children’s products, balancing durability with aesthetic appeal. Manufacturers often utilize the versatility of melamine powder to create attractive and safe toys for young consumers.

In the automotive industry, melamine moulding compounds are used to create a variety of components, such as interior trim pieces, handles and knobs. The material’s ability to withstand high temperatures and maintain dimensional stability makes it ideal for automotive interiors. In addition, its scratch resistance and impact strength help extend the life and quality of automotive parts.

Melamine moulding compounds are also used in various industrial applications where thermal and mechanical stress resilience is critical. From abrasives to grinding wheels, the material’s durability and dimensional accuracy make it the preferred choice for industrial products operating in challenging environments.

Many other applications are being explored…

The demand for melamine moulding compound in the market is expected to rise further with the evolution of economic development, environmental regulations, and technological advancements. As a melamine moulding compound manufacturer, Jinjiang requires us to focus on innovation and quality to maintain a competitive edge in the dynamic landscape of the market.

Tech Blog Is melamine breakable? When looking for tableware that is both aesthetically pleasing and durable, melamine (also known as melamine resin) products are often

Tech Blog Is melamine recyclable Melamine-based products—from durable tableware to scratch-resistant laminates—are widely used in household and industrial settings due to their heat resistance, hardness,

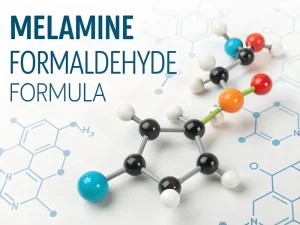

Tech Blog melamine formaldehyde formula What is melamine formaldehyde resin? Melamine formaldehyde (MF) resin is a high-performance thermosetting polymer known for its heat resistance, durability,

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE