Arc Resistance of Melamine Molding Compounds

Tech Blog Arc Resistance of Melamine Molding Compounds Melamine molding compounds are essential insulating materials for the electrical and instrumentation industries, widely used in mine

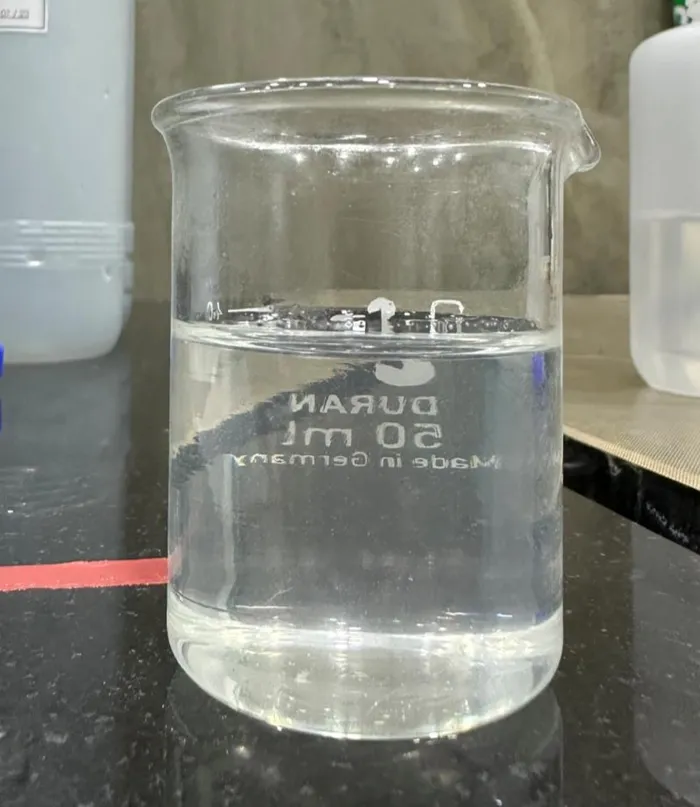

This article starts by explaining melamine and its physical and chemical properties. It then provides a detailed understanding of its solubility, whether it is soluble in water, and what is the best solvent for it. It provides a simple and clear answer to your questions about the solubility of melamine.

Melamine powder appears as a white monoclinic crystal.

It has a relatively high density of 1.573 g/cubic centimetre, about half greater than water’s.

When heated, it sublimates. It is almost odourless.

It is weakly alkaline and can form melamine salts when encountering acidic substances.

Under normal pressure, it decomposes at 354°C and sublimates at 300°C after rapid heating.

Melamine is slightly soluble in water, with a solubility of about 3.1 g/L at 20℃. The solubility changes with temperature, which is more soluble in hot water than cold water.

Specifically, the solubility of melamine in water below 40 ℃ is less than 0.9%, and its solubility gradually increases with increasing temperature. For example, the solubility is 6.4% at 100 ℃ and 7.1% at 110 ℃.

Melamine is soluble in formaldehyde, acetic acid, hot ethylene glycol, glycerin, pyridine, etc.

The solubility of melamine in acetone is 0.3 g/L, in ethanol it is 0.6 g/L, in dimethylformamide it is 0.1 g/L, and in ethyl cellosolve it is 11.2 g/L at 30 °C.

It is insoluble in acetone, ethers, carbon tetrachloride, and benzene.

Under weakly acidic conditions, the solubility of melamine is greater than that under neutral and alkaline conditions.

The solubility under alkaline conditions is slightly greater than that under neutral conditions.

Under certain pH conditions, the solubility increases with temperature.

Under strong acid and alkaline conditions, its solubility increases significantly with acidity and alkalinity.

It’s difficult to simply label one as the “best” solvent as it depends on the specific application and requirements.

For example, in the production of melamine-formaldehyde resins, formaldehyde is a key solvent. In some chemical processes where certain properties are needed, acetic acid or pyridine might be more suitable.

If considering factors such as availability, cost, environmental impact, and solubility under specific conditions, different solvents may be preferred in different contexts.

Melamine is soluble in formaldehyde, and this property is crucial in the manufacture of melamine-formaldehyde resins. These resins are widely used in various industries. They offer excellent durability and hardness in the field of adhesives and coatings.

In the leather industry, it serves as a tanning agent and filler, enhancing the quality and properties of leather products. It can also be used as a fabric treatment agent to prevent wrinkles and shrinkage, improving the durability and appearance of textiles.

Melamine is a compound with distinct physical and chemical properties. Its solubility in different solvents and under various conditions significantly influences its potential applications.

By understanding these properties and applications, we can make more informed decisions about using melamine in other fields and be aware of its potential risks.

Tech Blog Arc Resistance of Melamine Molding Compounds Melamine molding compounds are essential insulating materials for the electrical and instrumentation industries, widely used in mine

Tech Blog Influential Factors on Melamine Moulding Compounds Melamine moulding compounds are widely used in electronics, household utensils, and automotive parts due to their excellent

Tech Blog How to Slow Down Melamine Reactor Temperature Difference Rise Rate Melamine production via high-pressure processes (3rd-5th generation) relies heavily on reactor long-cycle operation.

Tech Blog Urea Industrial Use When most people hear the word “urea,” they immediately think of fertilizer. While it’s true that over 90% of the

Tech Blog How Is Urea Made for AdBlue AdBlue, the critical diesel exhaust fluid (DEF) for SCR systems, relies on high-purity urea (≥99.8%) as its

Tech Blog adBlue refractometer urea concentration testing AdBlue is the key to SCR (Selective Catalytic Reduction) systems, which rely on a precise 32.5% urea and

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE