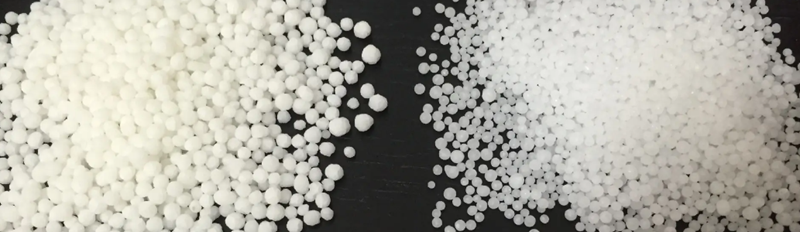

In the international fertilizer market, urea has granular urea and prilled urea. The difference in particle size originates from the difference in the granulation process and equipment used in the plant after the urea is produced. The following is an introduction to the difference between Granular Urea (large-particle urea) and Prilled Urea (small-particle urea).

1. The same nitrogen content:

Whether it is granular urea or prill urea, they are all urea, their nitrogen content is the same, and the nitrogen content is 46%.

2. Stability is the same:

Large particles of urea and small particles of urea and its composition are urea, at room temperature are not easy to volatilize, the stability is very good.

3. Chemical properties are the same:

Whether it is granular urea or prill urea, due to its composition is the same, therefore, its chemical properties are the same. At high temperatures, there are solids directly sublimated into ammonium cyanate, and decomposed into cyanic acid and ammonia.

4. Applicable crops are the same:

Both this two urea provide nitrogen for crops, and both can be used for wheat, corn, rice, cabbage, apples, pears, tomatoes, cucumbers, peppers, eggplants, and many other crops.

1. Different production processes:

At present, the preparation process of large particle urea is a dual drum fluidized bed process, which uses prill urea products as crystal seeds. The moisture and biuret in granular urea are slightly lower than those in small particle urea.

2. Different particle sizes:

According to the national production standard GB T 2440-2017 for urea, there are four specifications for urea particle size: 0.85-2.8 millimeters, 1.15-3.35 millimeters, 2-4.75 millimeters, and 4-8 millimeters. Granular urea particles refer to those with a diameter between 2.8-4.75 millimeters, and the particle size requirement for premium products is greater than 93%; Prill urea refers to a diameter between 0.85 and 2.85 millimeters, with a particle size requirement of over 90%.

3. Different intensities:

Granular urea particles have higher strength than ordinary urea, with a general strength of 6-8 times higher than ordinary urea. They are easy to transport and store and can prevent particles from getting damp and clumping.

4. Different fertilizer utilization rates:

Small particle urea dissolves in water faster, and is prone to loss and volatilization, while large particle urea has a higher hardness and slower dissolution rate in water, resulting in a significant improvement in fertilizer utilization efficiency, generally increasing by 10-30%.

5. Different quality:

In the process of producing large particle urea, the use of small particle urea products as crystal seeds can avoid the hollow phenomenon of urea particles and the shattering during the falling process, resulting in a lower crushing rate and higher product quality; However, small particles of urea are prone to being hollow and easily broken when falling, resulting in relatively poor quality.

6. Different moisture content:

Small particle urea generally has a higher water content in the production process due to its relatively small hardness; Due to its high hardness, large particle urea avoids the hollow phenomenon and can reduce the moisture content by 0.1% -0.2%, resulting in better product quality.

7. Different levels of biuret:

During the production process of small particle urea, due to high-temperature conditions, it is easy to generate biuret, which has a toxic effect on crop roots, and the content of biuret is relatively high; During the production process of large particle urea, it is required that the urine be evaporated and concentrated to 95% -96%, effectively reducing the production of urea. The urea content is lower, making it safer for crops.

8. Different shelf life:

Prill urea dissolves quickly in water and has a relatively short shelf life; However, large particle urea dissolves slowly in water and has a relatively long shelf life.

9. Different usage methods:

Prilled urea is suitable for topdressing due to its fast dissolution rate; However, the dissolution rate of large particle urea is relatively slow, making it more suitable as a base fertilizer and not suitable for quick-acting top dressing and flushing fertilization.

From the above analysis, it can be seen that although there are many similarities between granular urea and prilled urea, there are still many differences in their usage methods, which have been proven through experiments on various crops. The use of granular urea has a certain increase in production effect compared to prilled urea. Therefore, in production, suitable urea can be selected based on one’s own actual situation.

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE