China Melamine Analysis In May.2025

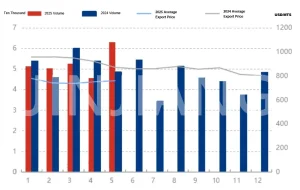

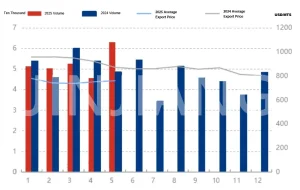

News China Melamine Analysis In May.2025 1. China Melamine Powder Export date In May 2025, melamine powder exports reached 63,000 tons, up 38.16% from the

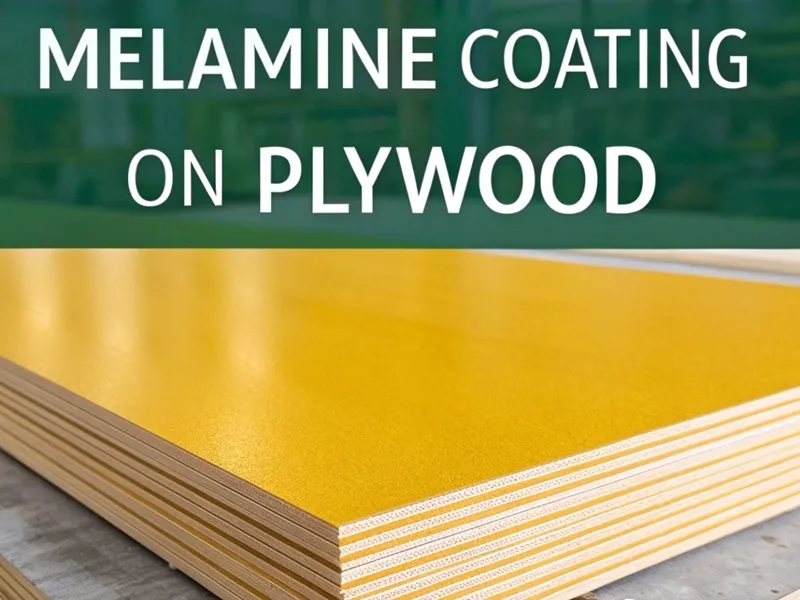

Plywood is a commonly used wooden material in construction and furniture manufacturing, favored for its excellent strength and stability. To further enhance plywood’s performance and aesthetics, melamine coating is becoming increasingly widespread. The coating not only gives plywood a unique appearance but also significantly improves its physical and chemical properties.

Melamine-coated plywood consists of a core (typically poplar, eucalyptus, or hardwood) laminated with melamine resin-impregnated paper under high heat and pressure. The resin forms a hard, non-porous surface miming natural wood grains or solid colors while offering enhanced functional properties.

Key Components

Core Material: Plywood (poplar, hardwood, or mixed cores) provides structural stability.

Melamine Resin: A thermosetting plastic derived from melamine and formaldehyde, creating a scratch-resistant, waterproof layer.

Surface Finishes: Options include matte, glossy, textured, or UV-coated finishes for added durability.

The main raw materials for making melamine coatings are melamine and curing agents. The selection and dosage of curing agents significantly impact coating performance, and common curing agents include hexamethylenetetramine. In addition, according to actual needs, some additives, such as plasticizers, defoamers, pigments, etc., will be added to improve the coating’s flexibility, eliminate bubbles, and give it different colors.

Surface treatment:

Before applying the melamine coating, it is necessary to treat the surface of the plywood beforehand. Firstly, use sandpaper to polish the surface of the plywood to remove burrs, impurities, and oil stains, making the surface smooth and even to enhance the adhesion between the coating and the plywood. Then, clean the surface with a cleaning agent to ensure no dust or residual impurities are present.

Coating methods:

Common coating methods include roller, spray, and immersion. Roller coating is the process of evenly applying melamine coating onto the surface of plywood using a roller. This method is suitable for large-area coating, with high production efficiency and relatively uniform thickness. Spraying uses a spray gun to atomize the coating and spray it onto the surface of plywood, which can achieve a finer coating effect and is suitable for products with higher appearance requirements. Dip coating completely immerses plywood in melamine coating to evenly adhere the coating to the surface. This method is ideal for plywood products with complex shapes but may result in difficulty controlling the coating thickness.

Curing process:

After coating is completed, the melamine coating must be cured. The curing process is usually carried out under certain temperature and time conditions, generally between 120-150 ° C, with a duration ranging from a few minutes to several tens of minutes. During the curing process, melamine resin undergoes a cross-linking reaction with the curing agent, forming a hard and wear-resistant coating. The control of curing temperature and time is crucial, as excessive temperature or time may cause the coating to turn yellow and brittle. Suppose the temperature is too low or the time is too short. In that case, the coating will not cure completely, affecting the performance of the coating.

Durability: Resists scratches, moisture, and stains, making it ideal for kitchens and high-traffic areas.

Fire Retardancy: Releases nitrogen gas when exposed to flames, slowing combustion.

Aesthetic Versatility: Available in wood grains, solid colors (e.g., Wenge), and custom designs.

Ease of Maintenance: Non-porous surfaces require minimal cleaning and resist microbial growth.

Cost-Effective: Cheaper than solid wood or ceramic alternatives.

In furniture manufacturing, melamine-coated plywood is widely used to decorate the surfaces of various types of furniture, such as wardrobes, cabinets, desks, dining tables, etc. Its beautiful appearance, good wear resistance, and chemical corrosion resistance make it an ideal material for this purpose, which can meet consumers’ dual needs for furniture aesthetics and practicality.

Melamine-coated plywood can be used for indoor decoration, such as wall decoration, suspended ceilings, floor laying, etc. Its waterproof and moisture-proof properties make it suitable for decoration in damp areas such as bathrooms and kitchens. Meanwhile, the rich selection of colors and textures can create different styles and atmospheres for indoor spaces.

In construction, melamine-coated plywood is often used as building formwork. Its excellent wear resistance and waterproof performance enable the formwork to maintain good shape and surface quality after multiple uses, facilitating the pouring and forming of concrete and improving construction efficiency and quality.

In summary, melamine coating on plywood has brought new opportunities for improving its performance and expanding its applications. With the increasing attention to environmental protection and health, the development of melamine-coated plywood will move towards a more environmentally friendly and high-performance direction.

Through reasonable process control and quality inspection, melamine-coated plywood can play an important role in multiple fields, providing people with better, more beautiful, and durable material choices for their lives and work.

News China Melamine Analysis In May.2025 1. China Melamine Powder Export date In May 2025, melamine powder exports reached 63,000 tons, up 38.16% from the

Tech Blog How Melamine Molding Compound Powder Is Revolutionizing Industrial and Household Products Melamine molding compound powder (MMC powder)-thermosetting polymers synthesized from melamine formaldehyde (MF)

Tech Blog Melamine Molar Mass Melamine powder (C₃H₆N₆) is a nitrogen-rich organic compound widely used in industrial and consumer goods, from durable tableware to flame-retardant

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE