Study on the effect of melamine on the growth of streptococcus thermophilus

Tech Blog Study on the effect of melamine on the growth of Streptococcus thermophilus Streptococcus thermophilus is a key lactic acid bacterium widely used in

Melamine powder is a compound used in various industries; however, as a chemical, it is not allowed to be added to food, and its presence in food can pose serious health risks.

Two foodborne illness outbreaks related to melamine have been reported in recent years. In March 2007, certain cereal-based pet food ingredients (e.g., wheat flour, wheat gluten, cornmeal, and rice protein concentrate) were intentionally adulterated with melamine to increase their total nitrogen content (66.6% nitrogen for melamine), resulting in an outbreak of severe kidney disease in dogs and cats in the U.S. This resulted in several deaths. As a result, several major companies recalled more than 5,300 pet foods.

In September 2008, milk and infant formula sold by Sanlu and 21 other Chinese dairy companies were contaminated with melamine, which causes kidney stones and kidney failure. As of November 2008, nearly 300,000 people have been sickened, and six infants have died.

There are still many evil people who only care about immediate interests and use the digestion stage of the Kjeldahl method to increase the protein content of food without regard to people’s health.

Therefore, the detection of melamine is essential to ensure food safety.

There are a variety method of detection of melamine.

1.Picric Acid Method:

The principle is to dissolve the melamine sample in water, add picric acid to the solution to make it precipitate with melamine, and then calculate the amount of melamine in the sample according to the amount of sediment generated.

2.Sublimation method:

The principle is to put the sample in a sublimation device so that the melamine in the sample is sublimated by heat and the mass of the remaining solid is accurately weighed.

These two methods are used in industry to detect melamine content with relatively high accuracy. Still, the analysis time is relatively long, and the operation is cumbersome, which is unsuitable for efficient and rapid detection.

3.Potentiometric titration:

It is more straightforward than the gravimetric method for detecting melamine in industry, and the experimental time is shorter, but the accuracy is not high. Its experimental principle is to titrate the solution containing melamine with a sulfuric acid standard solution and calculate the melamine content by the formula with the volume of sulfuric acid standard solution consumed at the equivalent point.

However, with the continuous progress of modern technology and analytical methods, the requirements for melamine detection in food are becoming higher and higher and must be more accurate and sensitive.

The above three methods do not apply to the current food testing.

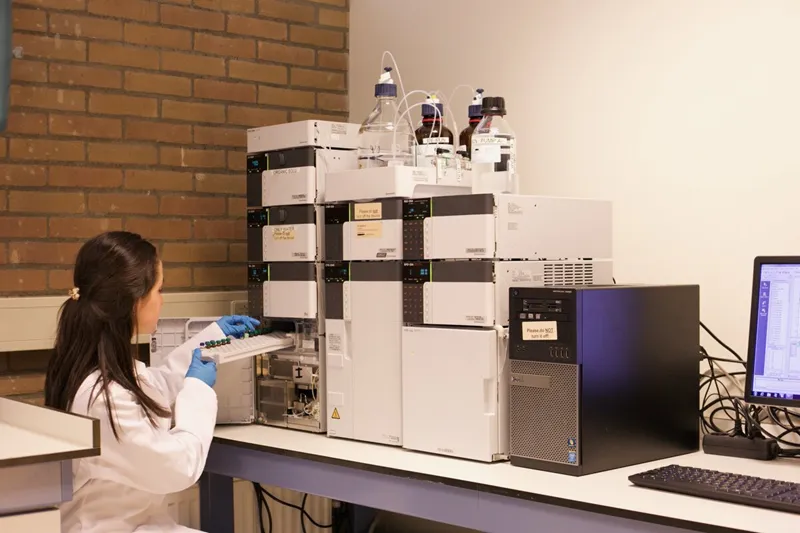

The principle is that the sample is extracted with trichloroacetic acid solution-acetonitrile, cleaned up by cation-exchange solid-phase extraction column, and then determined by high-performance liquid chromatography and quantified by external standard method.

Specific steps for the determination of melamine in milk by hplc.

(1) Sampling

①Liquid milk, milk powder, yoghurt, ice cream, milk sugar, etc.

Weigh 2 g (accurate to 0.01 g) of sample in a 50 mL stoppered plastic centrifuge tube, add 15 mL of trichloroacetic acid solution and 5 mL of acetonitrile, ultrasonic extraction for 10 min, and then shake extraction for 10 min, centrifuged for 10 min at not less than 4000 r/min. The supernatant was filtered through the trichloroacetic acid solution-moistened filter paper and then fixed to 25 mL with a trichloroacetic acid solution, and then 5 mL of filtrate was removed, and 5 mL of filtrate was added to 5 mL of trichloroacetic acid solution. mL of filtrate, add 5 mL of water and mix well to make the solution to be purified.

②Cheese, cream chocolate, etc.

Weigh 2 g (accurate to 0.01 g) of the sample in the mortar, add an appropriate amount of sea sand (4 to 6 times the mass of the sample) ground into dry powder, transfer to a 50 mL plug plastic centrifuge tube, with 15 mL of trichloroacetic acid solution to wash the mortar several times, the cleaning solution was transferred to the centrifuge tube, and then to the centrifuge tube to add 5 mL of acetonitrile, and then the rest of the operation of the same as in the “ultrasonic extraction”. 10 min, …… add 5 mL of water and mix to make the purified solution.

Note: If the fat content in the sample is high, you can use a liquid-liquid partition of hexane saturated with trichloroacetic acid solution to remove the fat before proceeding to the next step.

(2) Purification

Transfer the cleanup solution to the solid phase extraction column. Wash with 3 mL of water and 3 mL of methanol sequentially, pump to near dryness and elute with 6 mL of ammoniated methanol solution.

The flow rate of the whole solid phase extraction process did not exceed 1 mL/min. The eluate was blown dry with nitrogen at 50 ℃, and the residue (equivalent to 0.4 g of the sample) was fixed with 1 mL of mobile phase, vortexed and mixed for 1 min, and then passed through microporous filtration membrane for HPLC determination.

(3) Determination by HPLC

①HPLC reference conditions

a) Column: C8 column, 250 mm×4.6 mm (i.d.), 5 μm, or equivalent; C18 column, 250 mm×4.6 mm (i.d.), 5 μm, or equivalent.

b) Mobile phase: C8 column, ion-pairing reagent buffer (3.2.10)-acetonitrile (85+15, v/v), mixing.

Column C18, ion-pairing reagent buffer (3.2.10)-acetonitrile (90+10, v/v), mix well.

c) Flow rate: 1.0 mL/min.

d) Column temperature: 40°C.

e) Wavelength: 240 nm.

f) Injection volume: 20 μL.

② Plotting of standard curve

The concentration of 0.8, 2, 20, 40, and 80 μg/mL of melamine standard working solution was obtained by diluting the melamine standard stock solution step by step with the mobile phase. The concentration of the standard working solution was injected into the sample from the lowest to the highest, and the peak area-concentration graph obtained the standard curve’s regression equation. The HPLC chromatogram of the matrix-matched spiked melamine sample is shown in Figure A.1 in Appendix A.

③ Quantitative determination

The response value of melamine in the sample to be measured should be within the linear range of the standard curve; beyond the linear range, the sample should be diluted and analyzed again.

④ Calculation of results

The limit of quantification of this method is 2 mg/kg.

The principle is that the sample is centrifuged by protein precipitation, cleaned up by MCX phase extraction column, blown dry by nitrogen, derivatized by silylation, and then detected by gas chromatography-mass spectrometry (GC-MS/MS). Melamine is detected through the process of ionization.

The limit of quantification is 0.05 mg/kg.

The principle is that the sample is separated by liquid chromatography and then entered into the mass spectrometer for mass analysis. The ionization process detects melamine.

The limit of quantification is 0.01 mg/kg.

1. Inaccurate detection result: It may be caused by improper pretreatment, instrument failure, etc. The solution includes checking the sample pretreatment process. Solutions involve checking whether the sample pretreatment process is correct, cleaning and re-testing the instrumentation, and changing the detection method.

2. Slow detection speed: It may be caused by the slow operation of the instrument and equipment, or the detection method is not applicable, etc. The solution includes checking whether the instrument and equipment are working correctly. Solutions involve checking whether the instrumentation is standard, choosing the appropriate detection method, and optimizing the experimental conditions.

3. High cost of reagents: Both liquid chromatography and gas chromatography require a large number of reagents, which is costly. Solutions include choosing suitable detection methods, using alternative reagents, optimizing experimental conditions, etc., to reduce the cost of reagents.

Tech Blog Study on the effect of melamine on the growth of Streptococcus thermophilus Streptococcus thermophilus is a key lactic acid bacterium widely used in

Tech Blog Melamine Modified Polyurethane Polyurethane (PU) is a versatile polymer celebrated for its excellent wear resistance, oil resistance, chemical stability, and strong adhesion to

Tech Blog Spectrophotometric Method for Melamine Detection The spectrophotometric method for melamine detection is based on the complexation reaction between melamine powder, formaldehyde, and carbonyl

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE