Urea Industrial Use

Tech Blog Urea Industrial Use When most people hear the word “urea,” they immediately think of fertilizer. While it’s true that over 90% of the

Urea is an organic compound with the chemical formula CO (NH ₂) ₂. It contains about 46% nitrogen, making it an efficient and concentrated source of nitrogen fertilizer. In addition to agriculture, urea is also used in the chemical industry, animal feed, and even in diesel emission systems (DEF or AdBlue) to reduce emissions.

In 1828, German chemist Friedrich Waller shocked the scientific community by synthesizing urea from an inorganic compound (ammonium cyanate), overturning the theory that organic molecules could only be produced by living organisms. This breakthrough laid the foundation for modern organic chemistry and industrial urea production.

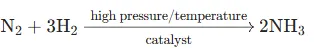

Ammonia (NH3): Produced through the Haber Bosch process, in which nitrogen (from air) and hydrogen (from natural gas or coal) react on an iron catalyst at high pressure (200-300 atm) and high temperature (400-500 ° C):

Carbon dioxide (CO₂): Originating from industrial processes such as fossil fuel combustion and ethanol production or captured from flue gas.

Ammonia and carbon monoxide react at high pressure (140-200 atm) and moderate temperature (130-150 ° C) to form ammonium formate.

Ammonium carbamate decomposes at lower pressures (10-20 atm) and higher temperatures (180-200 ° C) to produce urea and water.

This reaction is endothermic and requires careful temperature control to maximize urea yield (typically 50-70% per pass).

Unreacted substance recovery: Unconverted ammonia and CO ₂ are recycled back into the reactor to improve efficiency.

Urea solution concentration: Urea solution evaporates to form a concentrated melt (purity 99.5%).

Catalytic improvement: New catalysts (such as metal oxides) can increase reaction rates and reduce energy consumption.

Carbon capture integration: Some factories use CO ₂ to capture from power plants, aligning production with carbon reduction targets.

| Urea Type | Key Applications |

|---|---|

| Granular (95-98%) | Fertilizers (80% of use), DEF fluid |

| Prilled (99.5%) | Adhesives, plastics, skincare |

| Medical grade (99.9%) | Dialysis solutions, creams, diagnostics |

Global production: Over 180 million tons of urea are produced annually, with China, India, and the United States being the main producing countries.

Energy intensity: Producing 1 ton of urea requires approximately 3.5-4.5 gigajoules of energy, mainly from natural gas. Innovations such as electrified ammonia synthesis (using renewable energy) aim to decarbonize the process.

Carbon emissions: Industrial urea production emits approximately 1.5 tons of carbon dioxide per ton of urea, mainly from the use of natural gas. Carbon capture and storage (CCS) technology aims to alleviate this problem.

Ammonia runoff: Overuse of urea fertilizers can lead to water pollution and eutrophication, promoting the development of slow-release formulations.

So, how is urea made? It all started with the reaction of ammonia and carbon dioxide at high pressure and temperature to form urea. Although this process is simple in chemistry, it requires careful engineering design to ensure efficiency, safety, and environmental responsibility.

Understanding the urea production process helps us understand the technology behind one of the most important inputs in agriculture. Whether you are a student, farmer, or just curious, understanding how urea is made can provide valuable insights into the intersection of chemistry and food production.

Tech Blog Urea Industrial Use When most people hear the word “urea,” they immediately think of fertilizer. While it’s true that over 90% of the

Tech Blog How Is Urea Made for AdBlue AdBlue, the critical diesel exhaust fluid (DEF) for SCR systems, relies on high-purity urea (≥99.8%) as its

Tech Blog adBlue refractometer urea concentration testing AdBlue is the key to SCR (Selective Catalytic Reduction) systems, which rely on a precise 32.5% urea and

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE