China Melamine Analysis In May.2025

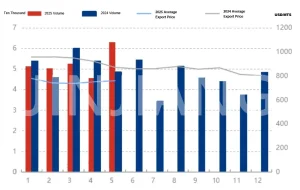

News China Melamine Analysis In May.2025 1. China Melamine Powder Export date In May 2025, melamine powder exports reached 63,000 tons, up 38.16% from the

In the manufacturing process of melamine tableware, using a melamine moulding powder preheater has many benefits, which significantly impact the production process and final product quality.

During the preheating process, melamine powder’s physical and chemical properties were optimized to ensure a more uniform reaction during the moulding stage, reducing the possibility of cracking or deformation in the finished product and resulting in higher-quality tableware. Compared to not preheating, this reduces the potential losses caused by poor product quality.

The durability of tableware has been enhanced, making our tableware more competitive in the market, as consumers prefer high-quality products. Consumers will choose products with better quality and longer lifespan, which can also increase sales and customer loyalty.

Preheating melamine powder will make the molecular distribution more uniform and the reaction more active. This uniform distribution results in a smoother surface finish during the moulding process, effectively eliminating water-like defects on the surface of tableware. This makes the surface of the tableware smoother and smoother and dramatically improves its brightness, making it look more beautiful, which can better meet consumers’ high requirements for product appearance.

A shiny and smooth surface often represents high quality, and such tableware will naturally attract more customers, making our products more popular. This enhanced visual appeal makes tableware more appealing to consumers, who are increasingly demanding products that function well and have a beautiful appearance. This advantage may be the decisive factor for product success in a market that values appearance.

After preheating, triamine powder has higher reactivity and flowability, allowing it to fill moulds faster and more evenly. This can significantly shorten the die-casting time. Reducing die-casting time translates into improving productivity in a production environment where time is a key factor. It enables manufacturers to produce more tableware in the same time frame, making better use of production resources such as machinery, labour, and energy.

This efficiency improvement helps to meet the growing market demand and contributes to overall cost savings and profitability. Initially, we could only produce a certain quantity of tableware simultaneously. By shortening the die-casting time, we can make more products, improving our production capacity and enabling us to better respond to market demand.

Based on these advantages, the production efficiency of tableware has been dramatically improved. Cost control, quality improvement, and reduced processing time work together to make the production process smoother and more efficient. In short, using a preheater to preheat melamine powder is essential in producing high-quality melamine tableware.

It has brought profound and positive effects to the entire production process, making our products more advantageous in the market and significantly improving our production efficiency.

At the same time, we need to know that choosing high-quality raw materials is equally crucial to ensuring the overall excellence of the final product. As China melamine powder and melamine moulding powder supplier, we are committed to providing first-class raw materials. Our strict quality control measures and advanced production technology ensure that the melamine and powder we provide have the highest purity, stability, and reactivity.

If you are looking for a high-quality supplier of melamine powder, please get in touch with us. Our products can help you improve the quality and performance of melamine tableware, consolidate your position in the market, and meet consumers’ growing demand for safe, durable, and aesthetically pleasing products.

News China Melamine Analysis In May.2025 1. China Melamine Powder Export date In May 2025, melamine powder exports reached 63,000 tons, up 38.16% from the

Tech Blog How Melamine Molding Compound Powder Is Revolutionizing Industrial and Household Products Melamine molding compound powder (MMC powder)-thermosetting polymers synthesized from melamine formaldehyde (MF)

Tech Blog Melamine Molar Mass Melamine powder (C₃H₆N₆) is a nitrogen-rich organic compound widely used in industrial and consumer goods, from durable tableware to flame-retardant

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE