China Melamine Analysis In May.2025

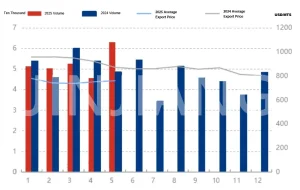

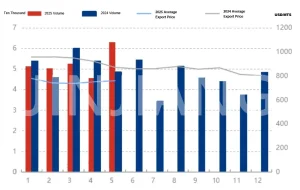

News China Melamine Analysis In May.2025 1. China Melamine Powder Export date In May 2025, melamine powder exports reached 63,000 tons, up 38.16% from the

Urea formaldehyde (UF Resin) is a thermosetting polymer derived from urea and formaldehyde. It is widely used in various industries due to its affordable price, fast curing speed, strong adhesive ability, good thermal and electrical insulation properties, and other characteristics.

In the woodworking and furniture industries, urea formaldehyde is mainly used as an adhesive. Its strong adhesive properties enable it to connect various types of wood. For example, plywood is made by bonding multiple layers of thin wood veneer using urea formaldehyde-based adhesive. The adhesive penetrates the wood’s porous structure, forming chemical bonds to create a sturdy and durable product. This makes plywood suitable for various applications, from furniture manufacturing to construction.

Particle board is another wood product that heavily relies on urea-formaldehyde adhesives. Small wooden particles are mixed with adhesive, then compressed and cured to form a flat and stable panel. Particle board is commonly used to produce furniture such as cabinets, wardrobes, and desks because of its relatively low cost and ease of processing. The strong adhesive properties of urea formaldehyde resin ensure that particleboard can withstand mechanical stress in daily use.

Urea formaldehyde resin is also used for surface treatment and coating wooden furniture. It can be formulated as clear paint to provide a protective layer on the surface of the wood. These coatings not only give the furniture a glossy surface but also protect the wood from moisture, scratches, and other forms of damage. In addition, the cured urea-formaldehyde resin’s hardness helps maintain the finish’s integrity over time, ensuring that the furniture looks very new.

Urea-formaldehyde foam is a popular thermal insulation material in the construction industry. It is injected into the cavities of walls, roofs, and floors to provide insulation. The foam expands to fill the space and form a barrier, reducing the heat transfer between the inside and outside of the building. This helps keep buildings warm in winter and cool in summer, thereby saving energy. Urea formaldehyde foam is also very light and easy to install, reducing the overall load of the building structure.

Urea formaldehyde resin can be used as an additive for cement-based products. It improves the workability of cement, making it easier to mix, pour, and form. In addition, it can enhance the strength and durability of cement, making concrete structures more resistant to cracking and other forms of damage. This is particularly important in large-scale construction projects such as bridges, buildings, and roads, as the integrity of concrete is crucial.

Urea formaldehyde-based pressure plates make decorative panels for interior walls and ceilings. These laminates can be printed with various patterns and colours, mimicking the appearance of natural materials such as wood, stone, or fabric. They are easy to install and provide an economically efficient way to enhance the aesthetic appeal of the interior of the building. The high hardness and scratch resistance of urea formaldehyde resin ensure that decorative panels can withstand the wear and tear of daily use.

In the textile industry, urea formaldehyde treats fabrics to prevent wrinkles. When applied to fabrics, urea-formaldehyde resin forms crosslinks between fibre molecules. This limits the movement of fibres, making the fabric less likely to wrinkle when worn or washed. The use of urea formaldehyde for anti-wrinkle treatment not only improves the appearance of the fabric but also enhances its durability. If you are concerned about formaldehyde residue, post-treatment with ammonium sulfate can minimize residual formaldehyde to the greatest extent possible.

Urea formaldehyde can also be used as a flame retardant for textiles. The resin decomposes and releases nitrogen-containing gases when exposed to high temperatures or fires. These gases dilute the oxygen concentration in the surrounding area and become a flame barrier spread. This makes processed textiles such as curtains, interior decoration, and clothing for firefighters and other industrial workers safer in terms of fire safety.

In the paper industry, urea formaldehyde is used to improve the strength of paper products. It can be added to a pulp during the manufacturing process. Urea formaldehyde resin forms crosslinking with cellulose fibres in pulp, improving the paper’s tensile strength and tear resistance. This is particularly important for paper products that require mechanical stress, such as cardboard boxes, packaging paper, and industrial paper.

Urea formaldehyde resin is also used to coat and size paper. Coating paper with urea-formaldehyde resin provides a smooth and glossy surface, making it an ideal choice for printing high-quality images and text. On the other hand, sizing involves treating paper with urea formaldehyde-based solution to make it more moisture resistant. This is important for paper products used in humid environments, such as food packaging paper and outdoor posters.

Urea formaldehyde resin is used to manufacture insulation components for the electrical and electronic industries. Its excellent electrical insulation performance makes it suitable for electrical switch enclosures, socket covers, and wire and cable insulation applications. The high thermal stability of urea formaldehyde resin ensures that these insulation components can withstand the heat generated by electrical equipment without degradation, thereby guaranteeing the safe operation of the electrical system.

Urea formaldehyde resin can be moulded into various shapes and sizes to produce electrical and electronic equipment components. These components, such as connectors, terminal blocks, and circuit board brackets, require high mechanical strength and dimensional stability. The ease of moulding and inherent strength and stability of urea formaldehyde resin make it an ideal material for these applications.

The widespread application of urea formaldehyde resin in multiple industries highlights its importance in modern manufacturing and construction. However, it is worth noting that urea formaldehyde releases formaldehyde gas, which is a potential health hazard.

Therefore, appropriate safety measures should be taken when using urea formaldehyde-based materials, such as adequate ventilation and low formaldehyde release products.

We are a Chinese supplier of urea formaldehyde resin, providing high-quality products. Please click here to learn more about our company. If you would like to purchase urea formaldehyde resin, please get in touch with us!

News China Melamine Analysis In May.2025 1. China Melamine Powder Export date In May 2025, melamine powder exports reached 63,000 tons, up 38.16% from the

Tech Blog How Melamine Molding Compound Powder Is Revolutionizing Industrial and Household Products Melamine molding compound powder (MMC powder)-thermosetting polymers synthesized from melamine formaldehyde (MF)

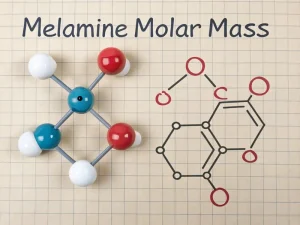

Tech Blog Melamine Molar Mass Melamine powder (C₃H₆N₆) is a nitrogen-rich organic compound widely used in industrial and consumer goods, from durable tableware to flame-retardant

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE