Arc Resistance of Melamine Molding Compounds

Tech Blog Arc Resistance of Melamine Molding Compounds Melamine molding compounds are essential insulating materials for the electrical and instrumentation industries, widely used in mine

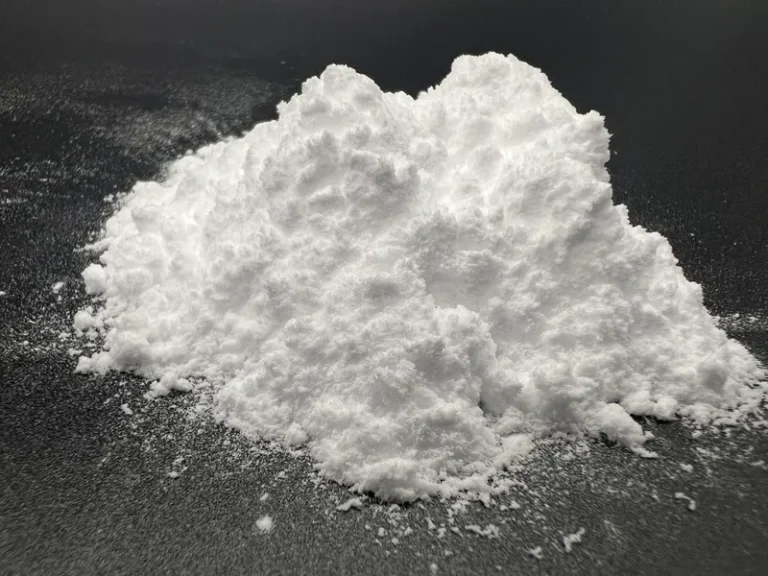

Melamine molding compound powder (MMC powder)-thermosetting polymers synthesized from melamine formaldehyde (MF) resin – are driving a materials revolution. With its excellent hardness, flame retardancy, and design diversity, MMC is replacing traditional plastics and metals in fields such as aerospace and kitchenware.

MMC forms a cross-linked polymer network through melamine (C₃H₆N₆) and formaldehyde (HCHO).

To solve the brittleness problem and improve processing performance, advanced modifications include:

Switchgear and insulators: The high resistance and heat resistance of MMC make it crucial for the following aspects:

Example: Siemens uses MMC in its low-voltage switchgear to ensure safety and longevity in industrial environments.

Underhood components: Resist engine heat and oil exposure

Impact: A leading automotive supplier used MMC to reduce component weight by 40% and improve fuel efficiency.

MMC powder exterior is superior to wood in humidity and is used for brands such as James Hardie’s composite wall panel system.

Durability for children: Fisher uses MMC in outdoor play equipment, which can withstand harsh use and weather conditions.

Melamine Molding Compound Powder have become transformative materials across industries. MMC’s performance, cost-effectiveness, and sustainability drive a manufacturing revolution, from fire-safe industrial components to environmentally friendly household products. With the advancement of nanotechnology and green chemistry, MMC will continue to replace traditional materials, ultimately promoting safer and more environmentally friendly manufacturing models.

Tech Blog Arc Resistance of Melamine Molding Compounds Melamine molding compounds are essential insulating materials for the electrical and instrumentation industries, widely used in mine

Tech Blog Influential Factors on Melamine Moulding Compounds Melamine moulding compounds are widely used in electronics, household utensils, and automotive parts due to their excellent

Tech Blog How to Slow Down Melamine Reactor Temperature Difference Rise Rate Melamine production via high-pressure processes (3rd-5th generation) relies heavily on reactor long-cycle operation.

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE