Urea Industrial Use

Tech Blog Urea Industrial Use When most people hear the word “urea,” they immediately think of fertilizer. While it’s true that over 90% of the

The issue of harmful emissions has been a pressing concern in modern transportation and industrial operations reliant on diesel engines.

Diesel exhaust fluid urea has emerged as a crucial solution, playing an essential role in taming the toxic gases released by diesel-powered machinery.

Its impact on reducing environmental pollution is significant and far-reaching, from long-haul trucks rumbling on highways to heavy-duty construction equipment at work sites.

Diesel exhaust fluid urea, in its chemical essence, is an aqueous urea solution. It’s meticulously formulated with a precise composition: 32.5% high-purity urea dissolved in deionized water.

This specific blend isn’t arbitrary; it’s designed to interface flawlessly with the selective catalytic reduction (SCR) systems that have become a staple in diesel engine technology. The urea, sourced to meet stringent industrial-grade quality benchmarks, forms the linchpin of the chemical reactions that lead to cleaner exhaust emissions.

Component | Percentage | Purpose |

Urea | 32.5% | React with nitrogen oxides in SCR process |

Deionized Water | 67.5% | Provide a stable medium for urea dissolution and proper fluid flow |

The selective catalytic reduction process is the heart of the action. When diesel fuel combusts in an engine, nitrogen oxides (NOx), a class of pollutants infamous for their role in smog formation, acid rain, and respiratory ailments, are churned into the exhaust stream.

As the hot exhaust gases surge through the SCR system, diesel exhaust fluid urea is introduced in a fine, atomized spray.

Once in the fray, the urea in the fluid swiftly undergoes thermal decomposition under the high temperatures of the exhaust. It breaks into ammonia (NH₃) and carbon dioxide (CO₂).

The liberated ammonia then takes center stage, engaging in a complex catalytic reaction with the nitrogen oxides over the surface of the SCR catalyst. The NOx molecules are converted into harmless nitrogen (N₂) and water vapour (H₂O) through meticulously choreographed chemical steps.

This transformation isn’t just a minor tweak; it can achieve remarkable NOx reduction efficiencies, often exceeding 90% in well-optimized systems, slashing the environmental footprint of diesel operations.

Industrial plants utilize state-of-the-art mixing equipment to blend high-purity urea with deionized water in the exact 32.5% ratio. The urea supply chain is rigorously vetted to guarantee its purity, warding off contaminants that could gum up the works in the SCR system.

The deionized water, too, undergoes a battery of purification processes to strip it of any minerals, ions, or impurities that might throw a wrench in the chemical reactions within the SCR matrix.

Quality control is the bedrock of diesel exhaust fluid urea production. Manufacturers run a gamut of tests, routinely verifying the urea concentration to ensure it’s dead-on at 32.5%. They scour for impurities, trace metals, chlorine, or other substances that could clog injection nozzles, foul the catalytic converter, or hobble the SCR process.

Physical parameters like density, viscosity, and pH are also monitored with a hawk’s eye to ensure the fluid’s seamless injection and optimal performance within the SCR system. Only when it passes all these quality hurdles will the fluid be deemed fit for purpose and released to the market.

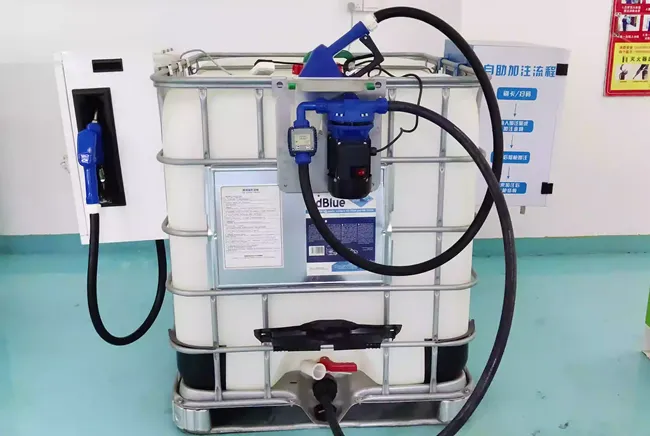

Diesel exhaust fluid urea must be stored in containers crafted from corrosion-resistant materials, typically polyethylene or stainless steel, to safeguard its integrity.

The storage environment should be shielded from direct sunlight and extreme temperature swings, with an optimal temperature range of around 5°C to 30°C.

This guards against urea crystallization, which can clog injection systems and degradation that might lead to ammonia release or altered chemical properties. Adequate ventilation is essential to dissipate ammonia fumes that could build up over time.

When handling diesel exhaust fluid urea, personnel should don appropriate personal protective equipment, including gloves, safety glasses, and, in some cases, respirators if working in confined spaces.

Spills, which can create slippery surfaces and pose a safety hazard, must be mopped up promptly using absorbent materials.

The injection systems in diesel-powered units that utilize the fluid require regular inspection and maintenance to ensure accurate dosing and to preempt blockages that could cripple the SCR process and lead to emission spikes.

Across the globe, regulatory bodies have been tightening the screws on diesel engine emissions. I

n Europe, the Euro standards have evolved through multiple phases, each ratcheting the requirements for NOx and other pollutants.

The United States Environmental Protection Agency (EPA) has likewise set lofty benchmarks that diesel vehicle and equipment manufacturers must clear. Diesel exhaust fluid urea and SCR technology have become the go-to answer for compliance, ensuring diesel-powered assets can keep running while minimizing their ecological toll.

In the automotive sphere, manufacturers have had to reengineer their diesel platforms to integrate SCR systems and accommodate diesel exhaust fluid urea.

This isn’t just about ticking regulatory boxes; it’s also a competitive edge. Eco-conscious consumers are likelier to opt for vehicles that meet and exceed emission standards.

From bustling construction sites to deep-mining operations, using diesel exhaust fluid urea is a must in the industrial domain.

It shields operations from hefty fines for non-compliance and paves the way for sustainable growth.

The diesel exhaust fluid urea market has been on a growth trajectory, mirroring the expansion of diesel-powered fleets and the tightening of emission regulations.

It spans many sectors, from on-road transportation to off-road industrial applications. Suppliers range from behemoth chemical manufacturers to local distributors, catering to the diverse needs of customers.

The fluid is available in various packaging options, from pint-sized containers for individual vehicle owners to hulking bulk tanks for industrial operations, making it accessible and convenient.

The cost of diesel exhaust fluid urea is influenced by multiple factors, including the price of raw materials (urea and deionized water), production costs, transportation, and market competition.

While the initial outlay for the fluid might seem like an added expense for diesel users, it’s offset by the long-term benefits of maintaining engine performance, meeting emission standards, and dodging costly fines for non-compliance.

Moreover, advancements in production technology and economies of scale gradually reduce the unit cost, making it more affordable for end-users.

Diesel exhaust fluid urea is a cornerstone in the battle against diesel engine emissions. Its seamless integration with SCR systems has redefined the environmental profile of diesel-powered operations.

From its precise production and quality control to careful storage and handling, with an eye on future innovations, it will continue to play a pivotal role in enabling sustainable diesel use across industries, safeguarding the environment, and ensuring compliance with ever-stricter emission regulations.

Here are some critical takeaways presented in a question-and-answer format:

Q: What is diesel exhaust fluid urea made of?

A: It’s an aqueous urea solution with 32.5% high-purity urea dissolved in deionized water.

Q: How does it work in SCR systems?

A: Urea decomposes into ammonia and carbon dioxide in the hot exhaust. The ammonia then reacts with nitrogen oxides over the catalyst to convert them into nitrogen and water vapour.

Q: Why is it essential to meet emission regulations?

A: It helps diesel engines comply with strict global standards like Euro and EPA regulations, reducing NOx emissions by up to 90% or more.

Q: What are the critical aspects of its production and quality control?

A: Precise mixing of urea and water, strict checks for impurities, and monitoring of physical parameters like density and pH.

Q: How should it be stored and handled?

A: In corrosion-resistant containers, at 5 – 30°C, proper ventilation is required, and safety gear is used during handling.

Q: What are the future trends related to it?

A: Advancements in SCR catalyst technology and integration with hybrid systems for better emission control.

If you have any questions about diesel exhaust fluid urea, pleaset contact us!

Tech Blog Urea Industrial Use When most people hear the word “urea,” they immediately think of fertilizer. While it’s true that over 90% of the

Tech Blog How Is Urea Made for AdBlue AdBlue, the critical diesel exhaust fluid (DEF) for SCR systems, relies on high-purity urea (≥99.8%) as its

Tech Blog adBlue refractometer urea concentration testing AdBlue is the key to SCR (Selective Catalytic Reduction) systems, which rely on a precise 32.5% urea and

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE