Is Melamine Breakable?

Tech Blog Is melamine breakable? When looking for tableware that is both aesthetically pleasing and durable, melamine (also known as melamine resin) products are often

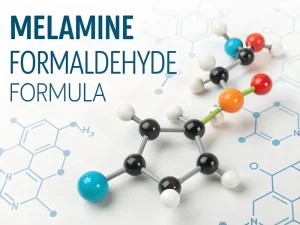

A5 melamine is also known as MF resin or melamine moulding compound(MMC). It is a polymer obtained by the reaction between melamine and formaldehyde.

After adding inorganic filler, the moulded products made of honey amine resin are rich in colour. They are mostly used for decorative panels, tableware, and daily necessities. Tableware looks like porcelain or ivory, is not easy to crack, and is suitable for mechanical washing.

A1 melamine, also known as UF resin or urea molding compounds(UMC), is made from urea, formaldehyde and melamine in small quantities as a substrate by adding other fillers (pulp), release agents, curing agents, pigments and so on after a certain plasticizing process.

Because of its good self-extinguishing, arc resistance, and good electrical insulation, easy coloring, product size stability, bright colors and other advantages, widely used in electronics, electrical appliances, automobiles, machinery, daily utensils and other industries, the most common familiar to you such as: electrical shells, wall switches, toilet seat, dominoes, chips, crafts and so on.

A5 and A1 melamine are the same amino resins.

Their main differences are as follows:

A5 main components for melamine formaldehyde resin (melamine formaldehyde resin) are about 75%, pulp (Additives) about 20% and additives (ɑ-cellulose) about 5%; cyclic polymer structure.

A1 main components for the urea formaldehyde resin (urea formaldehyde resin) are about 75%, pulp (Additives) about 20% and additives (ɑ-cellulose) about 5%;

A5 heat-resistant 120 ℃, A1 heat-resistant 80 ℃;

A5 can pass the national health quality testing standards, but A1 generally can’t pass the health performance testing and can only produce products that do not come into direct contact with food.

There is also a type of A3 melamine, which is a mixed product of A1 and A5.

MMC and UMC have characteristics, advantages, and disadvantages; the specific use of each takes what it needs.

From a comprehensive point of view, MMC is suitable for high temperatures, high-strength environments, and a wide range of applications; UMC is ideal for electric insulation, heat insulation, and other occasions; environmental protection and other aspects have advantages.

Tech Blog Is melamine breakable? When looking for tableware that is both aesthetically pleasing and durable, melamine (also known as melamine resin) products are often

Tech Blog Is melamine recyclable Melamine-based products—from durable tableware to scratch-resistant laminates—are widely used in household and industrial settings due to their heat resistance, hardness,

Tech Blog melamine formaldehyde formula What is melamine formaldehyde resin? Melamine formaldehyde (MF) resin is a high-performance thermosetting polymer known for its heat resistance, durability,

JINGJIANG MELAMINE POWDER

© JINJIANG MELAMINE